Our technology utilizes patented, methanogenic archaea as a biocatalyst to synthesize low-carbon e-methane from green hydrogen and carbon dioxide. Deployed as part of a Power-to-Gas (P2G) system, Electrochaea’s industry-leading biomethanation tech offers superior performance, flexible integrations and a whole host of benefits…

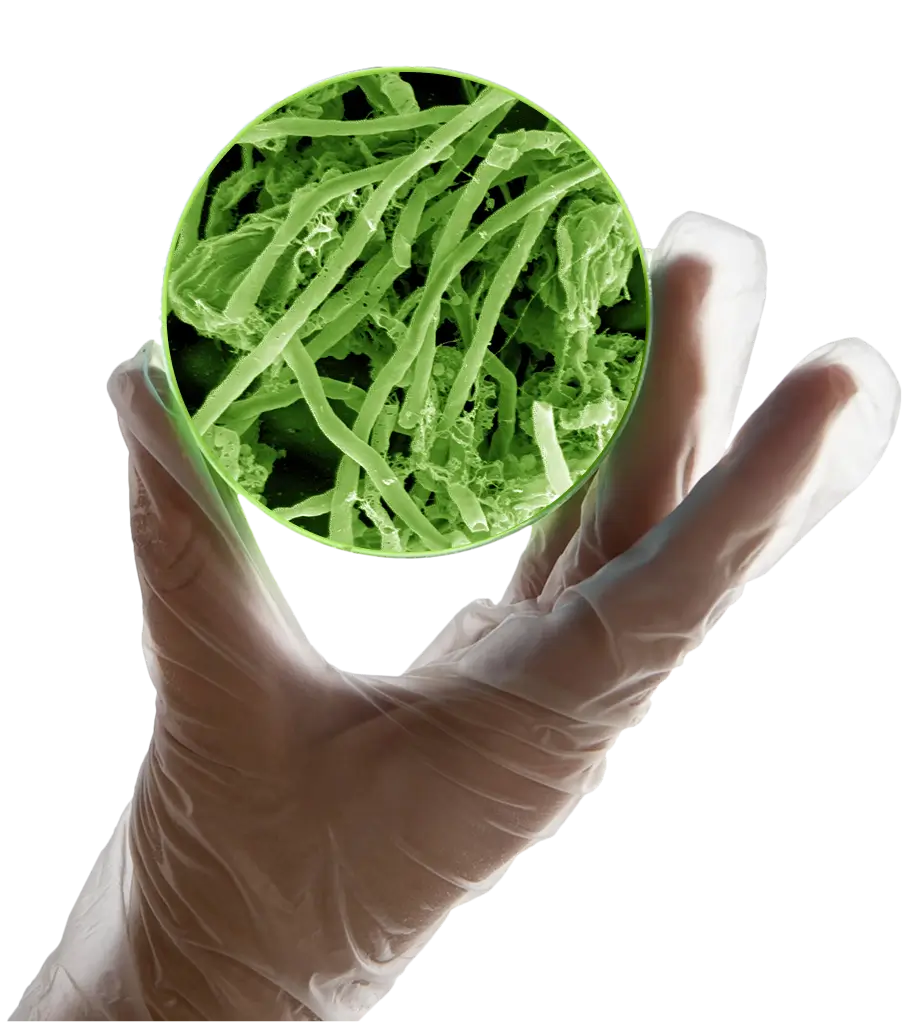

Our proprietary biocatalyst is a selectively evolved strain of methanogenic archaea, a single-celled microorganism that has populated Earth for billions of years. Found in a broad range of habitats, including volcanic hot springs, these resilient microorganisms are entirely self-replicating and self-maintaining when fed a diet of hydrogen, carbon dioxide and traces of nutrients.

The unique strain of archaea used in Electrochaea’s biomethanation technology was adapted by Prof. Laurens Mets at the University of Chicago to maximize its performance in climate-solving applications. As a result, our archaea exhibit several properties that facilitate optimal e-methane production, including high CO2 conversion efficiency, high tolerance to contaminants found in CO2 feedgas, no production of intermediates and rapid-reaction kinetics for large-scale commercial applications.

Our biomethanation technology operates as part of a holistic Power-to-Gas (P2G) system with two main inputs: green hydrogen and carbon dioxide (CO2).

Green hydrogen can be produced on-site via electrolysis, where renewable electricity and water are used to generate the hydrogen molecules, or via pyrolysis. Alternatively, green hydrogen can be delivered directly to the e-methane production site.

Our biomethanation tech is compatible with with any type of CO2, which means either Carbon-Capture technologies or Direct Air Capture (DAC) tech can be used to deliver biogenic CO2 or industrial CO2 into the bioreactor. Even raw biogas can be utilized as the source of CO2.

Both the green hydrogen and carbon dioxide are channeled into the bioreactor. Here, our proprietary archaea are maintained in a stirred solution at ~65°C and act as a biocatalyst to synthesize e-methane from the hydrogen and CO2. In addition to e-methane, water and heat are also generated via the process, and can be recycled or repurposed to optimize value.

Electrochaea’s strain of methanogenic archaea has been selectively evolved to deliver optimal performance across a variety of settings. With high CO2 conversion efficiency rates, no intermediate products released, high tolerance to impurities and rapid-reaction kinetics, our biomethanation tech is proven at commercial scale and can be used in conjunction with any type of CO2.

These technical benefits maximize e-methane outputs and minimize the need for extensive pre- and post-processing, thus simplifying the production process and delivering a higher ROI.

In addition to this, the unique properties of our archaea increase the applicability of our biomethanation tech and enable multiple sectors and industries to leverage the benefits of P2G e-methane production.

From decarbonizing global gas grids and cutting industrial emissions to next-gen biogas upgrading and powering heavy transportation with low-carbon eLNG, our innovative biomethanation technology is designed to deliver optimal environmental and economic benefits.

Our in-house team has extensive experience in the development, application and optimization of biological methanation and P2G tech. Furthermore, our sector-specific specialists are on hand to help you determine the best use case for our tech, based on detailed techno-economic feasibility assessments.

Balancing regulatory requirements and operational parameters with sustainability goals and fiscal growth targets, our team provides detailed guidance to ensure you find the best solution for your needs – but we don’t stop there.

With our pre-qualified network of engineering partners, operator training and continued technical support, Electrochaea’s expert team helps you to achieve optimal performance and maximum e-methane outputs.

Biological methanation (or ‘biomethanation’) is a biochemical process that converts hydrogen and carbon dioxide into methane and water using a biological catalyst. Electrochaea’s biocatalyst is methanogenic archaea that have been selectively evolved to deliver optimal performance when converting untreated CO2 from any source. When renewable electricity is used to generate ‘green hydrogen’ prior to the biomethanation process, the resulting gas is known as ‘e-methane’ – a renewable and low-carbon or carbon-neutral gas that’s identical to natural gas but has a significantly reduced carbon footprint.

Our proprietary biocatalyst – methanogenic archaea – have been carefully evolved to deliver enhanced conversion efficiency and optimal performance in climate-helping industrial applications.

This means our biomethanation technology is capable of converting hydrogen and untreated CO2 from any source into renewable e-methane. Additionally, our innovative biomethanation tech has a high tolerance to impurities within the CO2, produces no intermediates during the conversion process and features rapid-reaction kinetics that facilitate commercial-scale e-methane production.

With modular, scalable solutions and excellent load following capabilities, our biomethanation technology can be integrated in a variety of applications to facilitate e-methane production and accelerate the energy transition.

CO2 from numerous sources can be used in conjunction with our technology, including emissions from landfills, pyrolysis gas, waste-to-energy (W2E) plants, biogas plants, industrial / manufacturing sites etc. Our selectively evolved methanogenic archaea can tolerate a relatively high level of impurities in carbon dioxide, which means CO2 from any source can be used to generate e-methane. Both Carbon-Capture and Utilization (CCU) systems and Direct Air Capture (DAC) can be integrated alongside our biomethanation tech to utilize industrial or biogenic CO2.

Yes. A process called liquefaction can be used to convert e-methane gas into eLNG, which is classified as a Renewable Fuel of Non-Biological Origin (RFNBO) in the EU. eLNG can be used for a variety of purposes, including in hard-to-electrify sectors, such as shipping and heavy industry