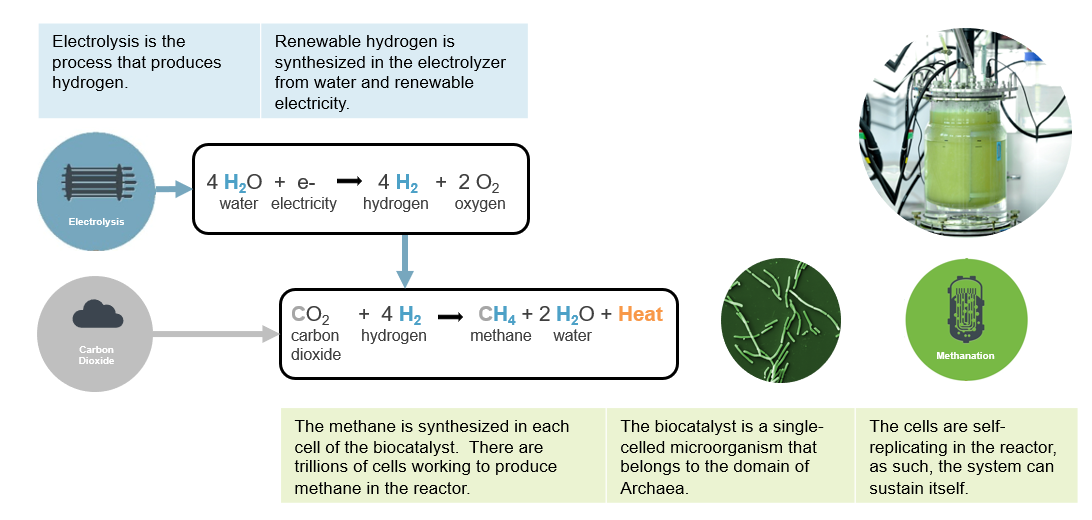

At Electrochaea, we use microorganisms, ancient archaea, as a biocatalyst to transform green hydrogen and emitted CO2 into one remarkable, renewable resource – synthetic methane.

How the Technology Works

Our patented biocatalyst converts green hydrogen and carbon dioxide into BioCat Methane, a pipeline-grade renewable gas. BioCat Methane is a synthetic methane that can be directly injected into the existing natural gas grid for immediate transmission and use or storage. Our bio-methanation process is a simple and cost-effective energy conversion system available for commercial projects.

BIOCATALYST

Our proprietary biocatalyst is a selectively evolved strain of methanogenic archaea, a single-celled microorganism that has populated Earth for billions of years. These organisms can be found in a broad range of habitats, including some of the most extreme environments on the planet, such as volcanic hot springs, salt lakes, or toxic soils. Archaea are extraordinarily resilient microorganisms that are self-replicating and when maintained in an anerobic environment and fed hydrogen, carbon dioxide and nutrients are self-maintaining.

The strain of archaea used by Electrochaea to synthesize BioCat Methane was adapted for this specific, climate-helping industrial application by Prof. Laurens Mets at the University of Chicago. Our archaea exhibit several properties including high conversion efficiency, no production of intermediates, tolerance to many contaminants typically found in industrial CO2 sources, and rapid reaction kinetics that allow scale-up to commercial applications.

SYSTEM DESIGN

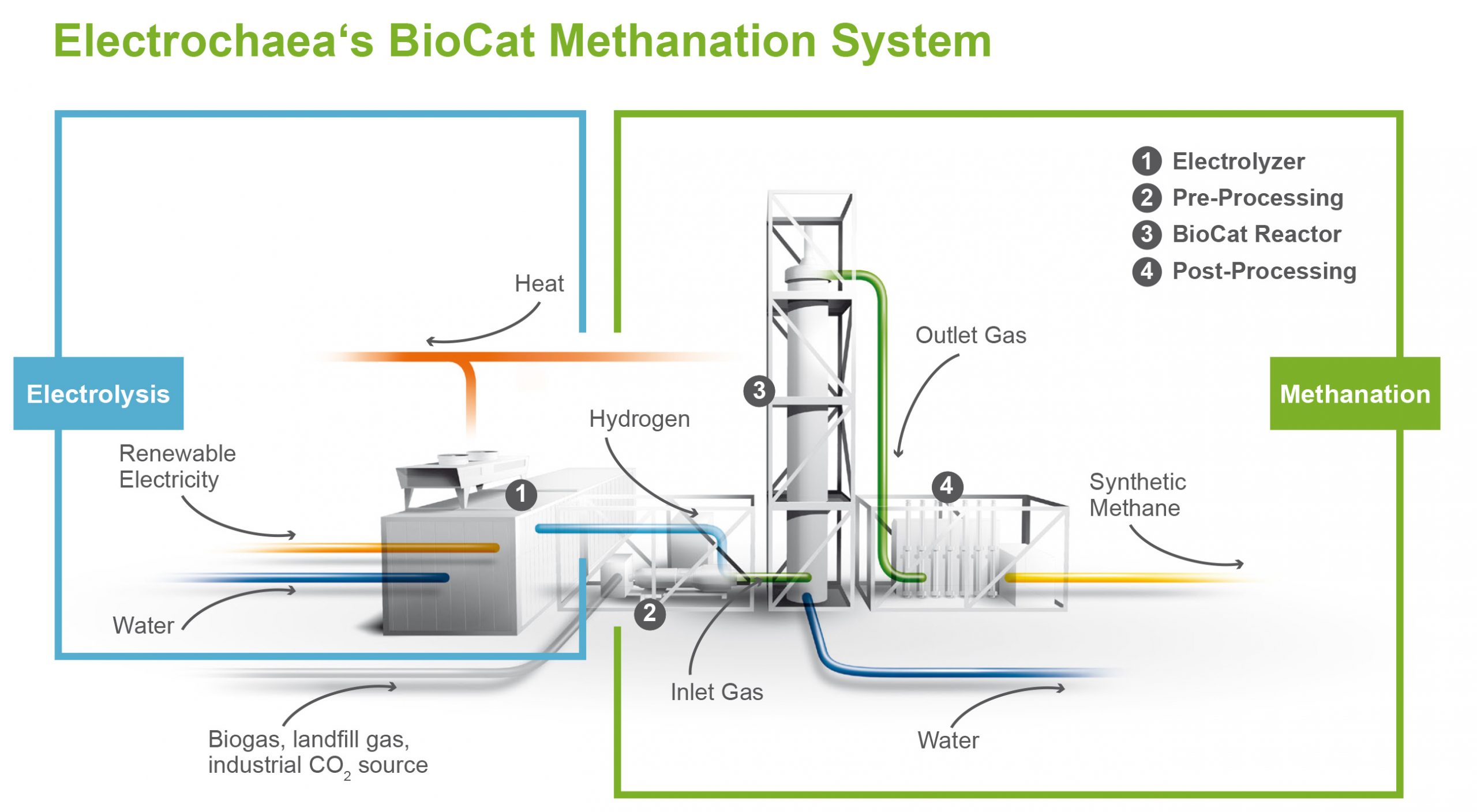

Electrochaea supports sustainable energy production and storage via a two-step power-to-gas (P2G) system.

STEP 1 Electrolysis

The first step uses an off-the-shelf electrolyzer to produce green hydrogen using emission-free renewable wind and solar energy.

STEP 2 Methanation

The second step combines green hydrogen with carbon dioxide from a biogenic or industrial source. These two components are fed into a bioreactor which houses the biocatalyst in a stirred solution at the optimum temperature (65 C). The product that leaves the reactor is Electrochaea’s BioCat Methane. Oxygen, heat and water are also valuable products from the process.